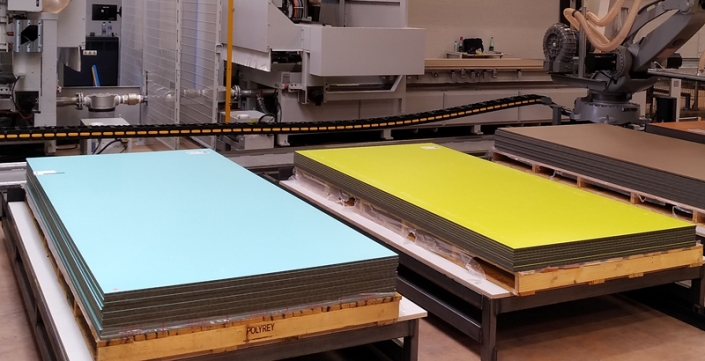

Automatic movement of panels.

The automatic system has been installed in a french Company, leader in Europe for the production of playground games, urban furnishings for green areas and physical activity outdoors areas.

The usage of milling materials like wood or resin panels, gave to the Company the chance to create a wide amount of products of this kind in short times and to satisfy the french and european market.

Nesting and weight of panels: the problem.

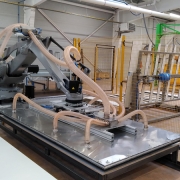

The production needs were to automatize the charge, the overturning and the discharge of panels until 3050 x 1550 mm and until 120 kg.

Without this system, to execute the milling work when the piece is finished, pantographs would do a milling at ¾ deep of the panel from the side.

On a single panel of large dimensions (3000 x 1500 mm), you can create different shapes and dimensions (nesting). So the placement of the panel for the milling on both sides needed to be really precise.

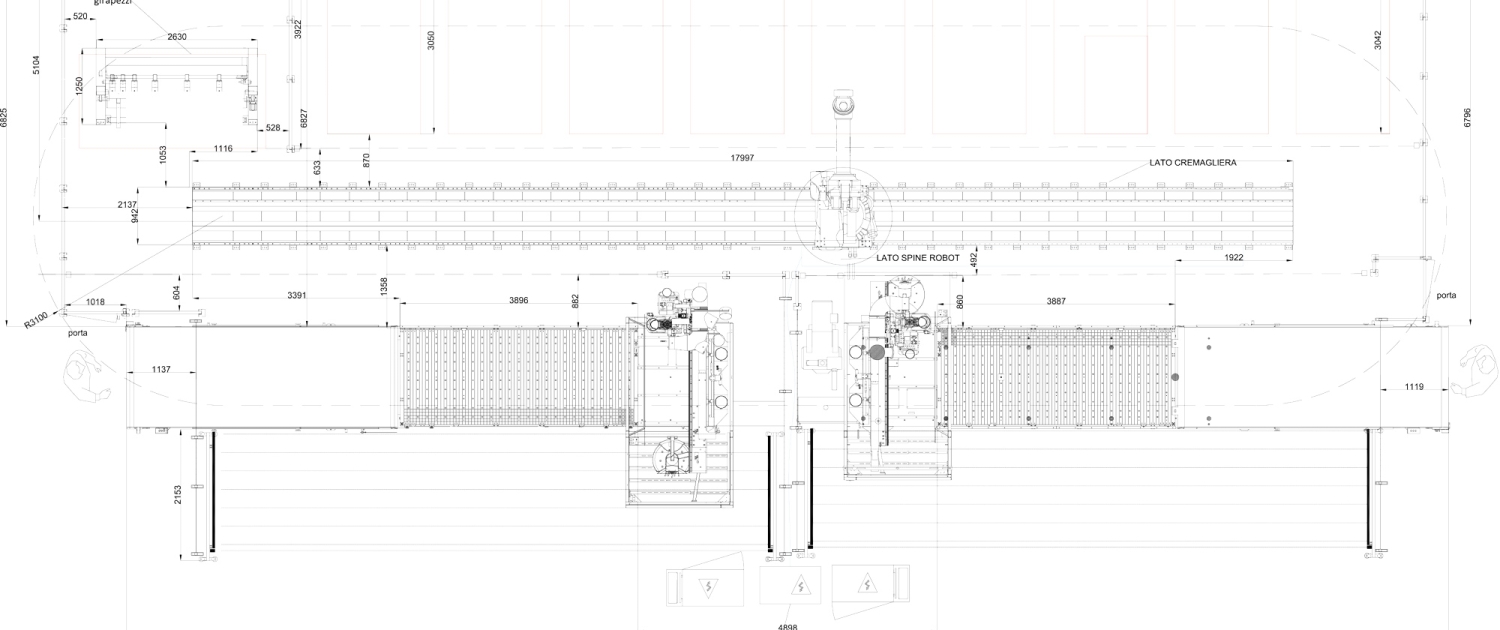

Furthermore, to operate with different drawings and panels, the system of loading needed to be designed to limit the machine stops.

The production needs:

La soluzione in movimento

System scheme

Are you interested in this solution?

Bosso Automation and Robotics, can make accurate and tailor-made estimates, evaluating needs, spaces, products to be handled and above all, your requests.